NDA

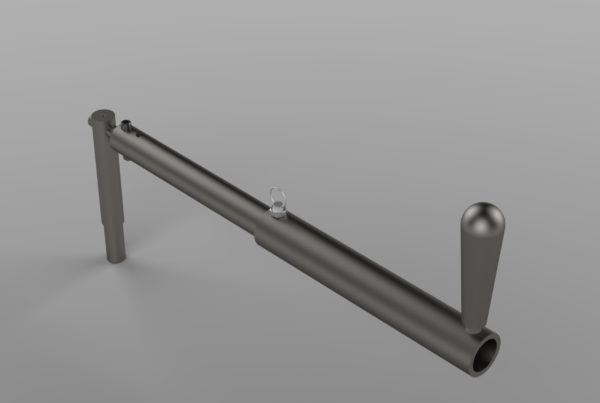

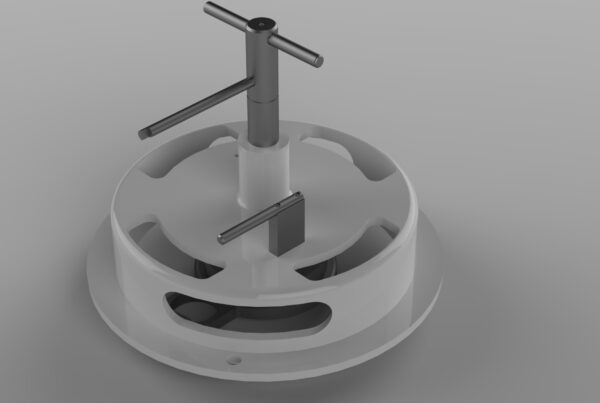

Reverse Engineering - Locomotive Brake Handle

Project Name:

Diesel Locomotive Service Brake Handle

Location:

UK

3D Scanning Used:

Vernier Used

Reverse Engineering Software:

Solidworks 2017 with Xtract 3D

Year Completed:

2018

Project Description:

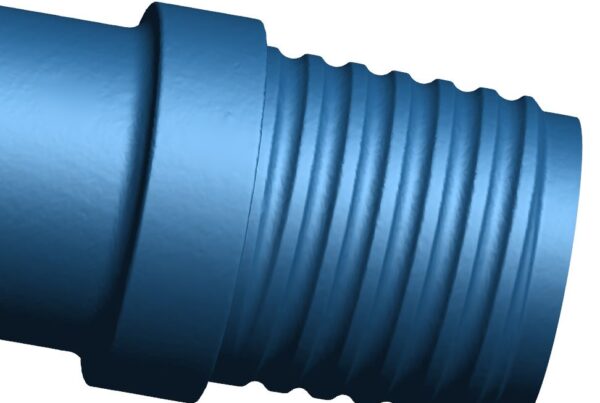

Reverse Engineering – This was a Locomotive brake handle designed in the USA and was a first for us. Our client approached us with a seized up brake handle from a diesel locomotive.

The handle was designed in the USA dating from the 1970’s.

The client wanted to carry out our Reverse Engineering process so the handle could be produced again in volume as they stock levels had diminished with no way of re-stocking.

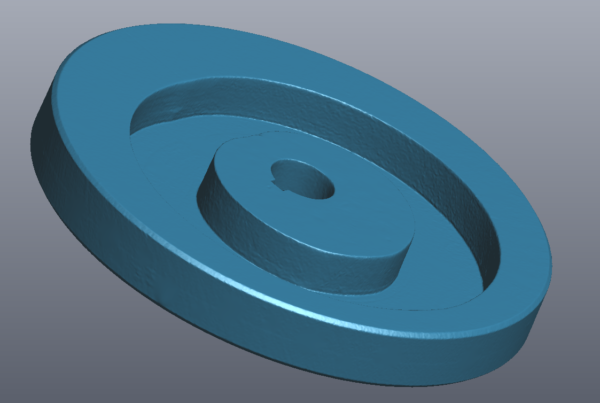

The handle has an internal adjustable custom CAM mechanism that works when a specific force is applied to the handle.

This allows the service operator to apply the brakes manually to the system without over torquing them and doing any damage to the braking system.

Obviously it was critical that we maintained this capability. We soaked the handle for a number of days until we were able to strip down the assembly.

The internal parts were also seized but eventually managed to release those as well. After considerable cleaning we determined that all parts could be measured with a Vernier or steel rule.

We set about measuring the parts and modelling them in Solidworks 2017. We made incremental changes to the design as it was previously designed for imperial measurement system so it was converted to metric & material specs were updated with more cost effective commercial grades.

The parts were manufactured to our drawings and the part underwent testing to ensure the crank worked at the specific torque setting and is now produced in volume.

Why not drop us a line here or call us to discuss your 3D Scanning or Reverse Engineering Project?

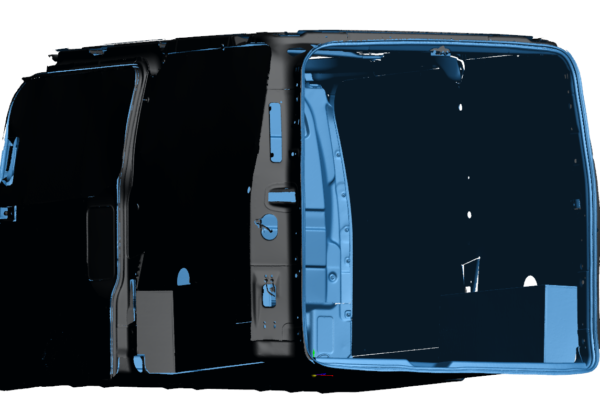

AUTOMOTIVE

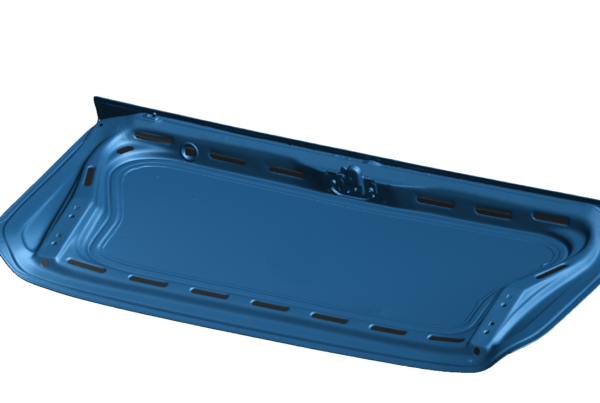

Reverse Engineering

Competitive Product Analysis

Repackaging

Interior Customisation

Modeling and Design

AEROSPACE

Rapid Prototyping

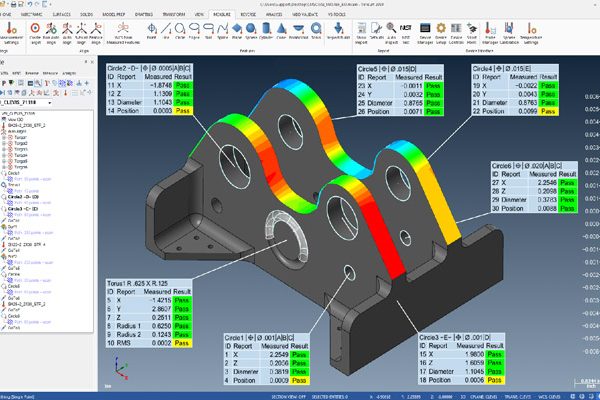

Quality Control Inspection,

(MRO) Wear & Tear Analysis

OEM Part Recycling

Reverse Engineering

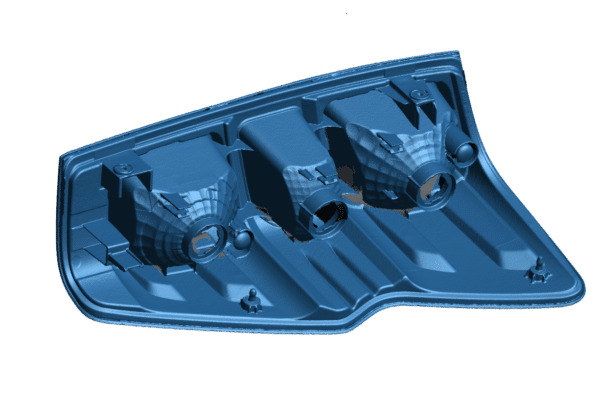

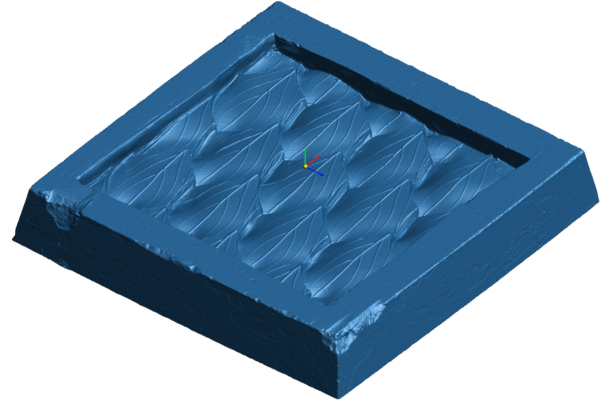

MOULD/TOOLING

Reverse Engineering

Quality Control

Tooling Wear Analysis

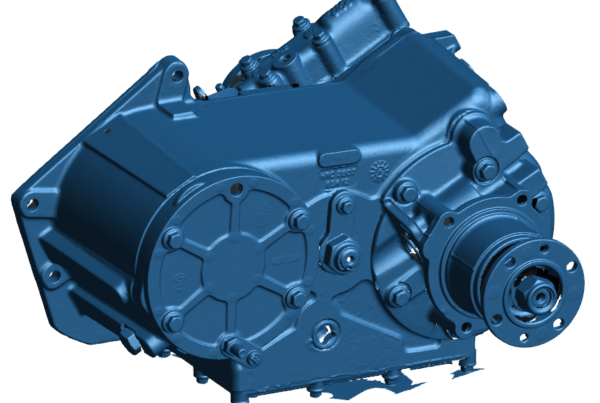

HEAVY INDUSTRY

Reverse Engineering

MRO Wear Analysis

Mechanical/Tooling

CASTINGS/FORGINGS

Cast part quality control inspection.

Machining processing design

Scan To Cad Verification

MEDICAL

Orthosis/Prosthesis Design and Manufacture.

CONSUMABLES

Modeling and design inspection,

Reverse engineering,

Tooling design,

VR & AR

CULTURAL/ART

Archaeology

Cultural Relics

Art

Sculptural Capture