Client:

Not Available Due To Non Disclosure Agreement

Location:

UK

3D Scanning Method

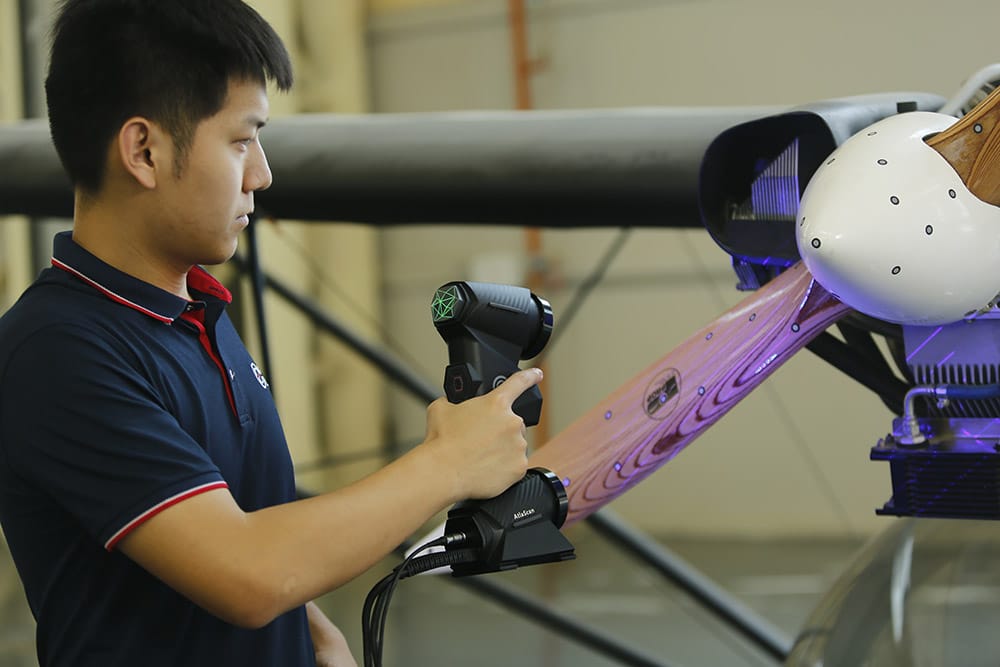

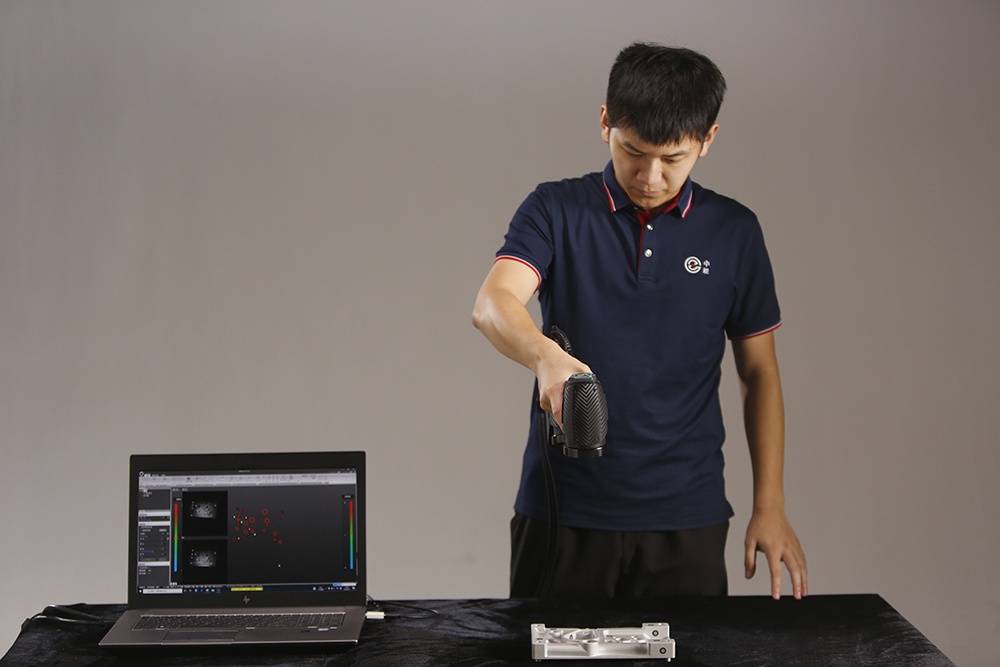

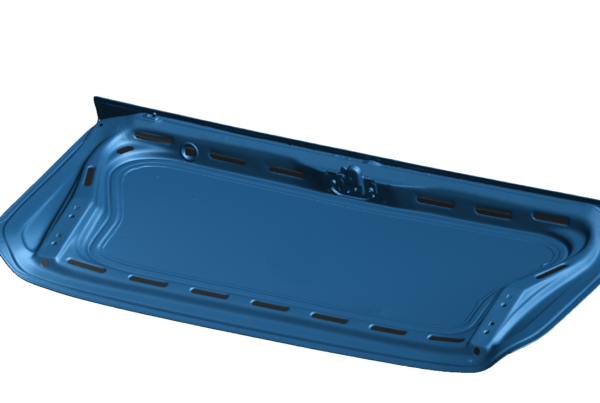

Atlascan 3D Laser Scanner (Blue)

Reverse Engineering CAD System

Post Processing done using various software.

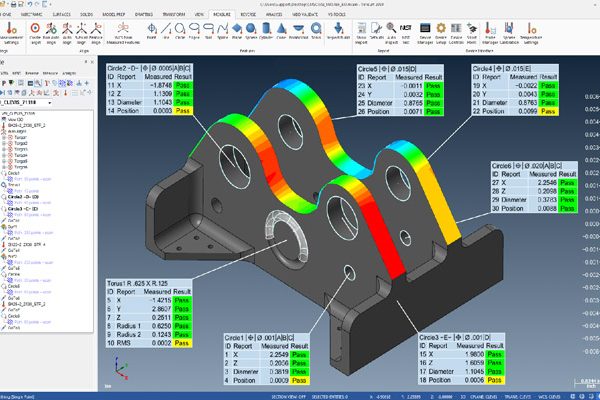

3D Scanning - Verisurf Inspection

We approached the Talyllyn Railway, the first preserved railway in the World, known affectionately as ‘The Railway with a Heart of Gold, as to whether any of our services would be of any use to them. The response was a resounding “Yes”. After some brief discussions it was determined that our scanning services could assist in checking the axle box positions & alignment on the Talyllyn Locomotive. The Talyllyn is one of the worlds oldest locomotives still in service & was currently undergoing a ten year overhaul.

At present they use tried and tested variety of measurement tools to check the positions between the axle boxes and this has been done for decades. However, it can take a couple of weeks to get the alignment data confirmed and the Engineers at Talyllyn were interested in finding a much quicker process yet just as reliable as their tried and tested methods.

We visited their workshops in Tywyn & set about 3D scanning the axle box apertures on the locomotive chassis with our Atlascan blue laser scanner. The day was a great success & we left with all the captured data. However, on the night time we sat down and reviewed the day & discussed the method we used. We determined that there was a quicker way to scan the chassis areas but maintain the same standard of accuracy. So we contacted the Engineering team and requested a 2nd visit the following week.

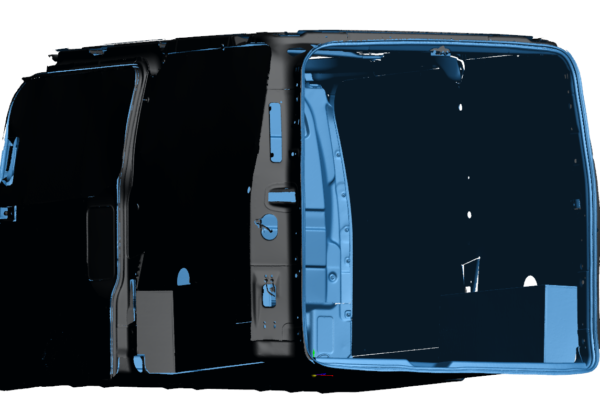

We spent some additional time on setup/preparation but we ended up scanning the chassis much quicker than on our previous visit. Once we had the data we then imported the geometry into Verisurf Metrology software. Verisurf is a metrology software which is so versatile it can be used with the latest and that the movement in the floor was as predicted creating noise on the scan. So our approach was to scan the van in 5 stages and then merge the scans at the end of the process.

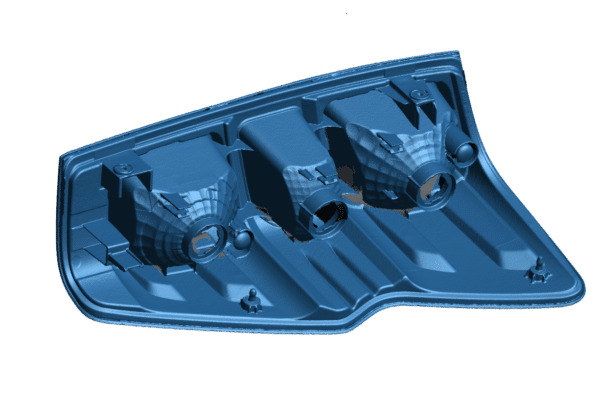

The merging of the scans created a root mean square deviation of 78 microns which the client was more than happy with. The client was supplied with an STL file in order for them to do the design work in-house.

Some Of The Services We Can Support You With.

AUTOMOTIVE

Reverse Engineering

Competitive Product Analysis

Repackaging

Interior Customisation

Modeling and Design

AEROSPACE

Rapid Prototyping

Quality Control Inspection,

OEM Part Recycling

Reverse Engineering

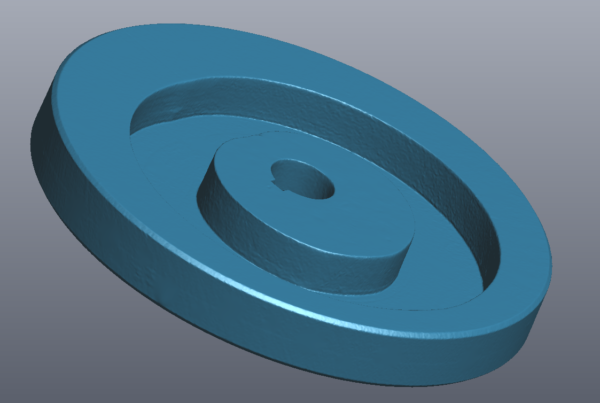

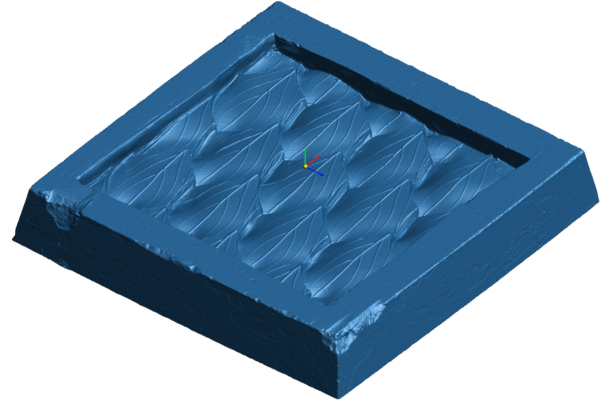

MOULD/TOOLING

Reverse Engineering

Quality Control

Tooling Wear Analysis

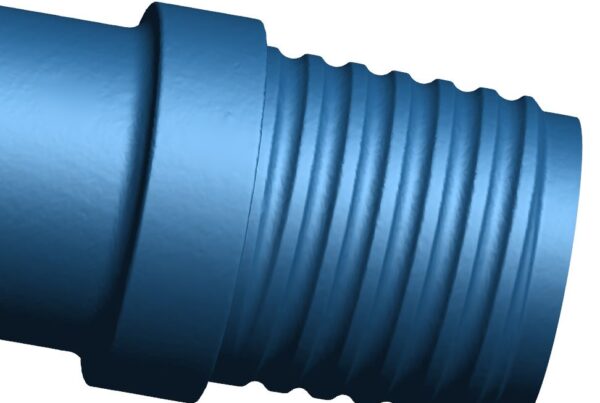

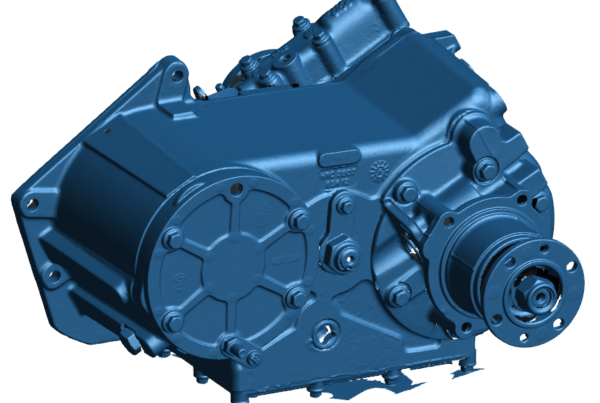

HEAVY INDUSTRY

Reverse Engineering

Mechanical/Tooling

Inspection

CASTINGS/FORGINGS

Cast part quality control inspection.

Machining processing design

Scan To Cad Verification

MEDICAL

Orthosis/Prosthesis Design and Manufacture.

CONSUMABLES

Modeling and design inspection,

Reverse engineering,

Tooling design,

CULTURAL/ART

Archaeology

Cultural Relics

Art

Sculptural Capture